YHT500 Portable Hardness Tester

Features

l Color display (320×240 TFT) with adjustable backlight.

l Add four new hardness scales, HRA, HB for D impact device of alloy tool steel; HV for cast aluminum alloy

l Add New user material function, to meet the need of user can test the special material.

l Converts to all common hardness scales (HV, HB, HRC, HRB, HRA, HS).

l English displaying and menu operating, the operation is easy and convenient.

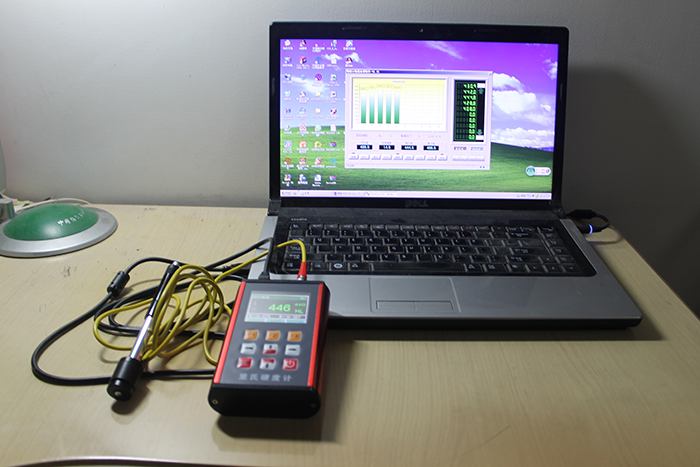

l With USB interface, multiple communication modes are adopted to meet customized requirements of various users.

l Equipped with 7 types of impact devices which need not to be recalibrated when changing them, the system can identify the type of impact device automatically.

l Max 600 groups(impact times:32-1)of data can be stored at internal non volatile data storage.

l Upper and lower limit of hardness can be preset; When the tested value exceeds the limits, alarm will send out automatically to make convenient for the requirements of batch measurements.

l Back light display has been used to make convenient for the use in poor light.

l Test values software calibration function.

l Material of “cast steel” is added; HB values can be read out directly when D/DC impact device is used to measure “cast steel” work piece.

l Printer be separated from main unit and copies of testing results can be printed as required.

l Using lithiumion rechargeable batteries, Continuous working period: approx. 200 h (no back light on).

l Software of PC can be installed according to the requirements of user, the function will be more powerful to satisfy the more strict demands of quality control and management.

Technical Specifications

Hardness scale | HL, HB, HRB, HRC, HRA, HV, HS |

Memory | Data memory: 0-300 groups (impact times: 32-1) |

Measuring range | HLD ( 17-960 ) HLD |

Standard Impact Device | D |

Optional Impact Devices | DC, D+15, G, C, DL |

Power | 3.7 V LithiumIon battery |

Continuous Working time approx. | 100 h (without back light on) |

Display LCD, | Color Whole Angle TFT LCD |

Operating temperature | -10°C ~40°C |

Humidity | ≤90% |

Dimensions | 154×82×35mm (main unit) |

Weight | 0.6kg (main unit) |

Testing Range

Material | Hardness Method | Impact Device |

D/DC | D+15 | C | G | E | DL |

Steel and cast steel | HRC | 17.9-68.5 | 19.3-67.9 | 20.0-69.5 |

| 22.4-70.7 | 20.6-68.2 |

HRB | 59.6-99.6 |

|

| 47.7-99.9 |

| 37.0-99.9 |

HRA | 59.1-85.8 |

|

|

| 61.7-88.0 |

|

HB | 127-651 | 80-638 | 80-683 | 90-646 | 83-663 | 81-646 |

HV | 83-976 | 80-937 | 80-996 |

| 84-1042 | 80-950 |

HS | 32.2-99.5 | 33.3-99.3 | 31.8-102.1 |

| 35.8-102.6 | 30.6-96.8 |

Hammered steel | HB | 143-650 |

|

|

|

|

|

Cold work tool steel | HRC | 20.4-67.1 | 19.8-68.2 | 20.7-68.2 |

| 22.6-70.2 |

|

HV | 80-898 | 80-935 | 100-941 |

| 82-1009 |

|

HRA | 60.7-92.6 |

|

|

|

|

|

HB | 232-625 |

|

|

|

|

|

Stainless steel | HRB | 46.5-101.7 |

|

|

|

|

|

HB | 85-655 |

|

|

|

|

|

HV | 85-802 |

|

|

|

|

|

Gray cast iron | HRC |

|

|

|

|

|

|

HB | 93-334 |

|

| 92-326 |

|

|

HV |

|

|

|

|

|

|

Nodular cast iron | HRC |

|

|

|

|

|

|

HB | 131-387 |

|

| 127-364 |

|

|

HV |

|

|

|

|

|

|

Cast aluminum alloys | HB | 19-164 |

| 23-210 | 32-168 |

|

|

HRB | 23.8-84.6 |

| 22.7-85.0 | 23.8-85.5 |

|

|

HV | 83.2-648.2 |

|

|

|

|

|

Brass(copper-zinc alloys) | HB | 40-173 |

|

|

|

|

|

HRB | 13.5-95.3 |

|

|

|

|

|

Bronze (copper-aluminum/copper-tin alloys) | HB | 60-290 |

|

|

|

|

|

Wrought copper alloys | HB | 45-315 |

|

|

|

|

|

Standard Delivery

Standard Delivery | No. | Name | Qty | Note |

1 | Main unit | 1 |

|

2 | D type impact device | 1 |

|

3 | Small supporting ring | 1 |

|

4 | Nylon brush (A) | 1 |

|

5 | Battery Charger | 1 |

|

6 | Paper for printing | 1 |

|

7 | High value Leeb test block | 1 |

|

8 | Instruction Manual | 1 |

|

9 | Instrument Case | 1 |

|

Additional Optional Delivery | 1 | Rubber Sleeve | 1 |

|

2 | Wristlet | 1 |

|