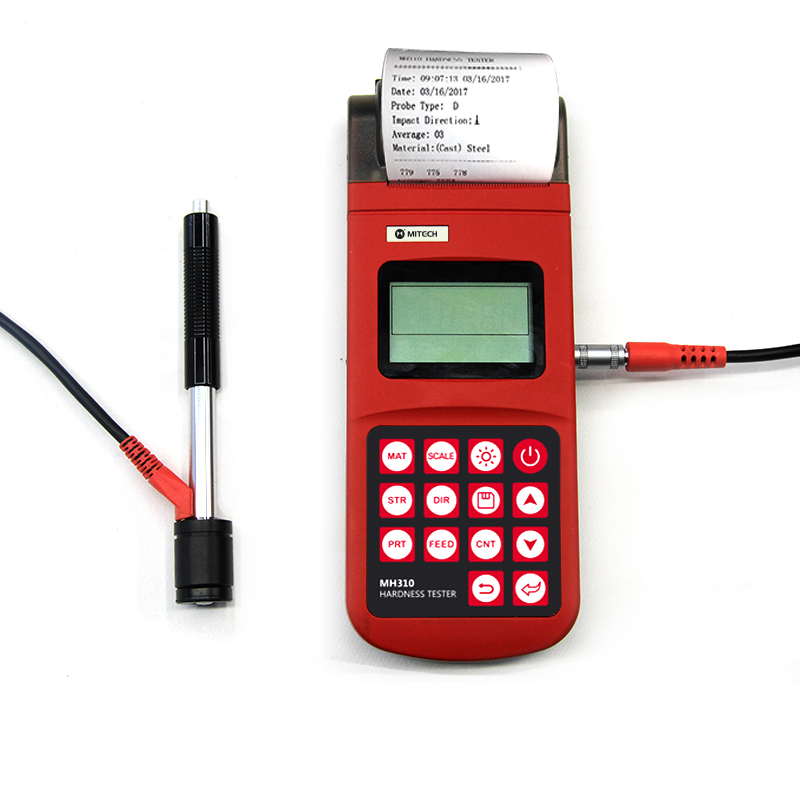

MH310 Portable Leeb Hardness Tester

Product Overview

MH310 portable Leeb hardness tester, based on Leeb hardness measuring principle, quickly and easily on-site test the hardness of series meta materials, support free conversion between Leek, Brine , Rockwell hardness scale and others, it uses high contrast segment LCD to display clear, stable performance. integrated high speed thermal printer ,which can print on-site measurements. It is widely used in annealing, tempering, quenching , quality control for the work piece; hardness testing for machine too and automobile chassis ; on site hardness testing of in service non-removable parts; quality testing for hardware, forging, machine too s and special steels; quality control for batch production process and so on.Good quality and effective cost ,which is a wise choice for regular need of hardness testing.

Technical Specifications

Error and repeatability of displayed value showed in Table below.

No. | Type of impact device | Hardness value of Leeb standard hardness block | Error of displayed value | Repeatability |

1 | D | 760±30HLD 530±40HLD | ±6 HLD ±10 HLD | 6 HLD 10 HLD |

2 | DC | 760±30HLDC 530±40HLDC | ±6 HLDC ±10 HLDC | 6 HLD 10 HLD |

3 | DL | 878±30HLDL 736±40HLDL | ±12 HLDL | 12 HLDL |

4 | D+15 | 766±30HLD+15 544±40HLD+15 | ±12 HLD+15 | 12 HLD+15 |

5 | G | 590±40HLG 500±40HLG | ±12 HLG | 12 HLG |

6 | E | 725±30HLE 508±40HLE | ±12 HLE | 12 HLE |

7 | C | 822±30HLC 590±40HLC | ±12 HLC | 12 HLC |

l Measuring range:HLD(170~960)HLD

l Impact direction: vertically downward, oblique, horizontal, vertical upward, automatically identify

l Material: steel and cast steel,cold work tool steel, stainless steel, Grey cast iron,Nodular cast iron, cast aluminum alloys,BRASS(copper-zinc alloys),BRONZE(copper-aluminum/tin alloys),Wrought copper alloys

l Hardness Scale:HL、HB、HRB、HRC、HRA、HV、HS

l Paper Roll: data storage

l Display:High-contrast Segment LCD

l Data memory:100 measurement series.(relative to impact times 32~1)

l Battery : 6V,(Ni-MH battery pack)

l Power Supply: 9V/500mA

l Recharge Time: 2.5~3.5hours

l Standby Time: About 150hours (with default brightness)

l Communication interface:USB1.1

Features

l Based on the principle of Leeb hardness testing theory. It can measure many metallic material

l One main unit can match to 6 impact devices

l Support Steel ,when using D/DC sensor to test steel,it can show HB directly,no need to check manually.

l High-contrast Segment LCD ,easy to use

l Software calibration automatically.

l 100 groups (impact times 32 ~ 1) hardness measurements, each set of data includes single testing value, average value, measurement date / time, impact direction, frequency, material, hardness, and other information.

l Real-time display the remaining battery power, charging progress is displayed while charging.

l High brightness EL back-light display for easy use in dimly environment.

l Automatic sleep and shutdown and other power-saving features

l Integrated thermal printer with the instrument as a whole, and quiet operation, fast print speeds, you can print the test report on-site.

l Equipped with PC software (optional), with functions of measurements transmission ,value storage management, statistical analysis of the measured value, the print report of measured value, batch setting instrument parameters , to meet the higher requirements of quality for activities and management.

l Small size, portable, stable and reliable performance, suitable for harsh environment field operations, prevent from vibration, shock and electromagnetic interference.

l Dimension:212mm×80mm×32mm

Application fields

l Die cavity of molds

l Bearings and other parts

l Failure analysis of pressure vessel, steam generator and other equipment

l Heavy work piece

l The installed machinery and permanently assembled parts

l Testing surface of a small hollow space

l Requirements of formal original record for test results

l Material identification In the warehouse of metallic materials

l Rapid testing in large range and multi-measuring areas for large-scale work piece

Application conditions

l Surface temperature can’t be overheat less than 120℃.

l Surface roughness should not to be too large, otherwise it will cause errors. The surface of the work piece must be exposed metallic luster, smoothing and polish without Oil

l The specimens with 2-5kg or thin walled specimens overhangs should be supported with some object in order to avoid the specimen deformation ,bending and movement caused by impact for medium-sized work piece ,it shall be placed on a flat and hard surface, the sample must be placed absolutely smoothly,without any shake, for heavy samples more than 5kg, it can be measured dire without any support.

l Portable Leeb hardness tester has strict requirements for sample thickness , the minimum thickness shall comply with regulatory a(see instructions).

l For work piece with hardened layer on surface,the depth of hardened layer should conform to regulatory

l For lighter parts, please make it tightly coupled with support ,two coupled surface layer should must be conform flat and to smooth, the coupling gel should not to be too much. The direction of the test shall be perpendicular to the coupling plate; if the work piece is a large plate, pole or bending material , even the weight and thickness is ok ,it may still cause deformation and instability, resulting in test values error, it should be reinforced or supported at the back of the test points.

l Magnetic of work piece should be less than 30 gauss.

l For artifact-surface : The work piece surface is preferably flat. When the curvature radius R of measured surface is less than 30mm,the.work pieces should be tested with the small support ring the shaped support rings.

Working Conditions

l Working temperature:-10℃~+50℃,

l Storage temperature -30℃ ~ + 60℃,

l Relative humidity : ≤90%,

l The surrounding environment should avoid of vibration, strong magnetic field, corrosive medium and heavy dust.

Configurations

| No. | Item | Quantity | Remarks |

Standard Configuration | 1 | Main unit | 1 |

|

2 | D type impact device | 1 |

|

3 | Standard test block | 1 |

|

4 | Power adapter | 1 |

|

5 | Cleaning brush (A) | 1 |

|

6 | Small support ring | 1 |

|

7 | Ni-MH battery pack | 1 | In product |

8 | Printer paper roll | 1 |

|

9 | Manual | 1 |

|

10 | ABS instrument package case | 1 |

|

Optional Configuration | 1 | Cleaning brush (B) | 1 | For use with G type impact device |

2 | Other type of support rings |

|

|

3 | Other type of impact devices |

|

|

4 | DataPro software | 1 |

|

5 | Communication cable | 1 |

|